Introduction

Cooling towers are among the most critical ventilation and cooling equipment in industries, buildings, and power plants. These systems use circulating water to dissipate excess heat from equipment, thereby cooling the water. One of the key components of a cooling tower is the packing (or fill), which increases the contact surface between water and air for more efficient evaporation.

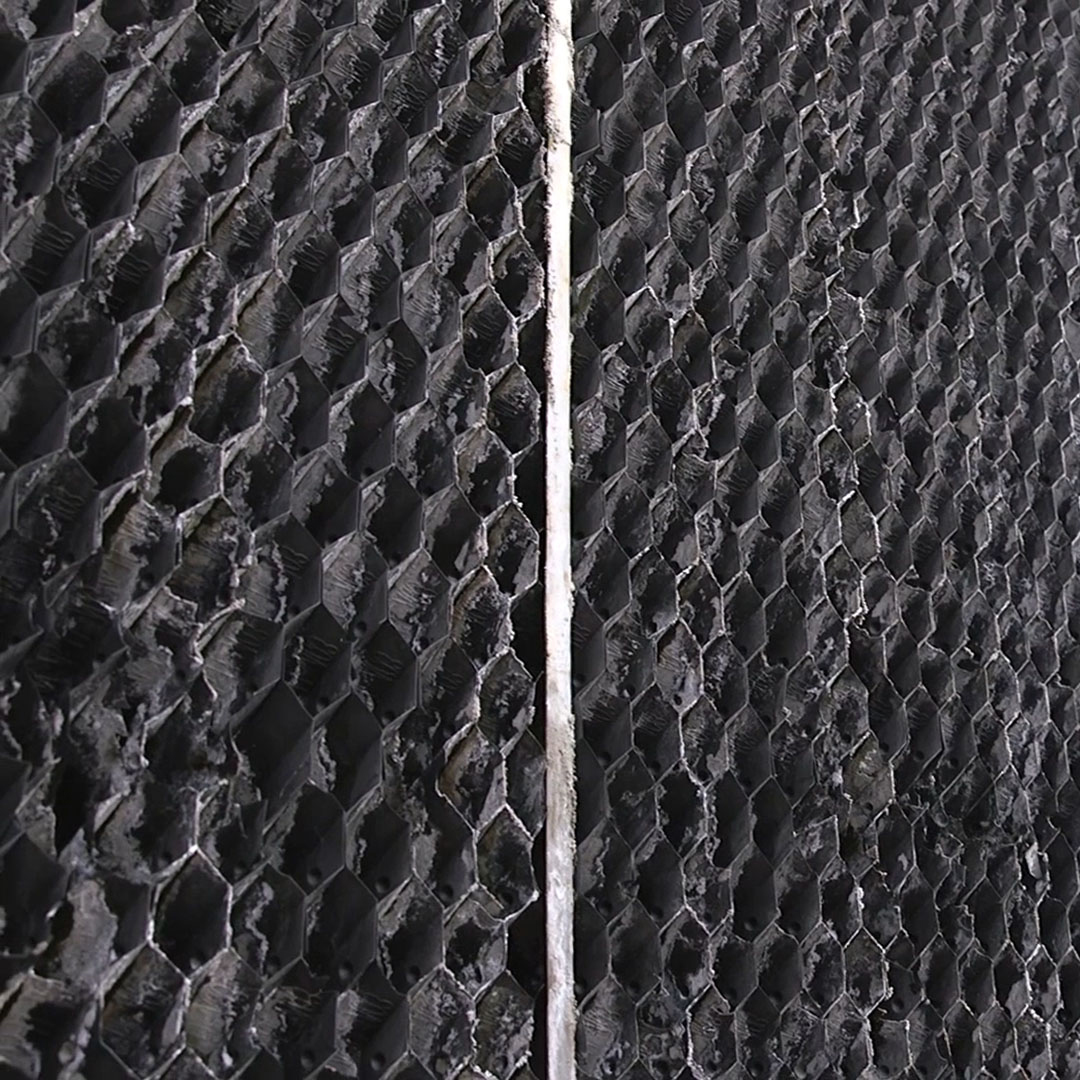

Over time, however, deposits, algae, and suspended particles accumulate on the packing, causing blockages and reducing system efficiency. In this article, from the Sardab Sazan Gostar Shargh series, we aim to provide a practical review of the causes of deposits in packing, how to prevent them, and the best cleaning and maintenance methods.

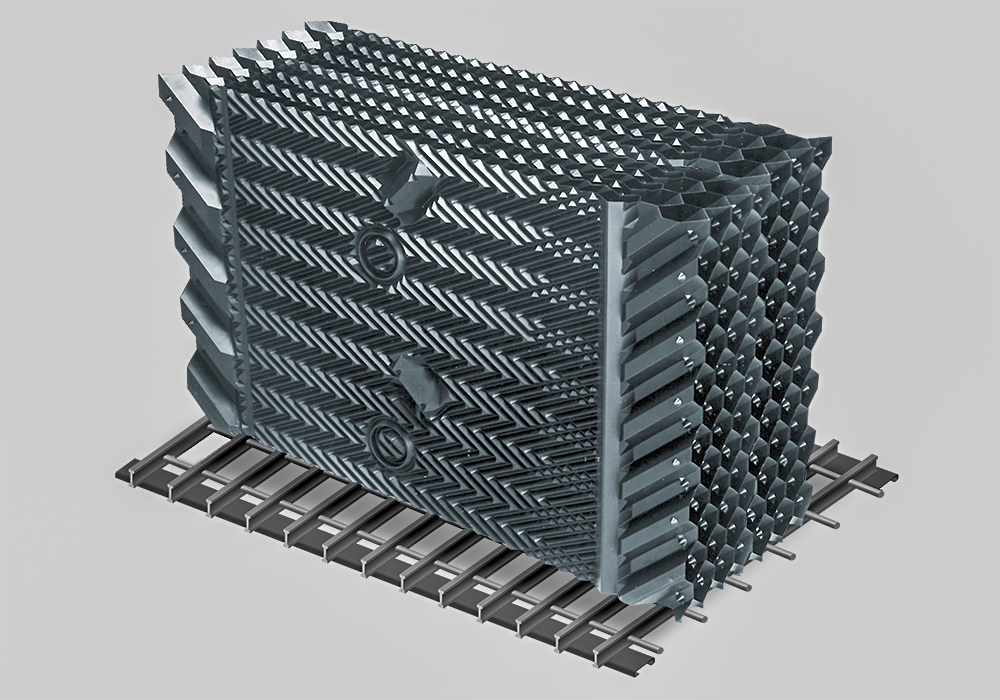

What is cooling tower packing and what role does it play?

Cooling tower packing is essentially the heart of the cooling tower system. This component is made of PVC, PP, or wood and is responsible for increasing the contact surface between the circulating water and the incoming air flow, allowing the evaporation and heat transfer process to occur with maximum efficiency.

Packings are divided into two main types:

- Film Fill: suitable for cleaner water, with high efficiency.

- Splash Fill: suitable for conditions where the water contains more particles or impurities.

If the packings become clogged or scaled, the water flow is disrupted and heat exchange is impaired; as a result, the outlet water temperature rises and the cooling tower’s performance decreases.

Main Causes of Scaling and Clogging in Cooling Tower Packings

Clogging of packings is a common but preventable issue. The main causes of this phenomenon are:

- Poor circulating water quality: The presence of salts, lime, magnesium, and suspended particles leads to the formation of hard deposits in the packing channels.

- Lack of proper water treatment or filtration system: The entry of dirt, algae, and suspended particles into the water circuit gradually clogs the packing.

- Unbalanced water flow: If the water flow is too low or too high, evaporation does not occur uniformly, creating dry or saturated areas that become prone to scaling.

- Irregular maintenance and lack of periodic cleaning: Accumulated sludge and debris in the cooling tower basin gradually enter the packing over time.

- Algae and bacterial growth: In the warm and humid environment of the cooling tower, the growth of microorganisms causes sticking and clogging of the packing.

The impact of clogged packing on cooling tower performance

Scaling and clogging of the packing is not just a cosmetic issue; it directly affects system performance and costs:

- Reduction of water cooling efficiency by up to 30%

- Increased energy and fan electricity consumption

- Increased pressure on circulation pumps

- Increased risk of corrosion and deterioration of the tower structure

- Reduced lifespan of the packing and other cooling tower components

Therefore, regular cleaning of the packing not only maintains the system’s performance but also reduces repair costs and energy consumption.

Methods for Cleaning Cooling Tower Packing

For washing and removing deposits from cooling tower packing, two main methods are typically used:

1.On-site cleaning (direct method)

This method is used when scaling or clogging is not severe. The procedure includes:

- Shut down the tower and disconnect the power supply.

- Drain the system water and perform an initial wash with high-pressure water.

- Use safe cleaning agents or descaling chemicals at a temperature of 40–50 °C.

- Rinse thoroughly until all deposits and sludge are completely removed.

- Final disinfection with a biocide solution to eliminate algae and bacteria.

2.Soaking cleaning method (Immersion method)

When the packings are heavily scaled:

- The packings are removed from the tower.

- They are immersed in a large tank or vat filled with water and a special cleaning solution.

- After several hours, they are washed with a brush or water pressure and reinstalled.

In case of decay or deformation of the fills (packings), it is recommended to install new fills instead of cleaning them.

Maintenance Tips and Prevention of Fill Clogging

To increase the lifespan of the fill and prevent the recurrence of problems, observe the following:

- Monthly inspection of fills (packings) and nozzles to ensure uniform water distribution

- Utilizing a filtration and water treatment system to remove suspended solids

- Adding standard anti-scaling and anti-algae chemicals (biocides) to the circuit

- Annual thorough cleaning (wash-down) of the cooling tower

- Replacing the fills (packings) every 4 to 5 years or if damaged

How often should a cooling tower fill (packing) be replaced?

Depending on the type of fill and water quality, fills should typically be replaced every 5 years. In areas like Mashhad, where water hardness is higher, this interval may be reduced to 3 to 4 years. Using high-quality, heat-resistant fills supplied by companies such as Sardab Sazan Gostar Shargh can increase the system’s lifespan several times over.

Conclusion

Scaling and clogging of cooling tower fills are among the most critical factors that can severely reduce the efficiency and lifespan of a cooling tower. Heavy repair costs can be prevented through proper water treatment, periodic servicing, and professional washing of the fills. For professional cleaning, fill replacement, and cooling tower maintenance in Mashhad and throughout Iran, you can contact the experts at Sardab Sazan Gostar Shargh to review your unit’s status and provide the best solution.