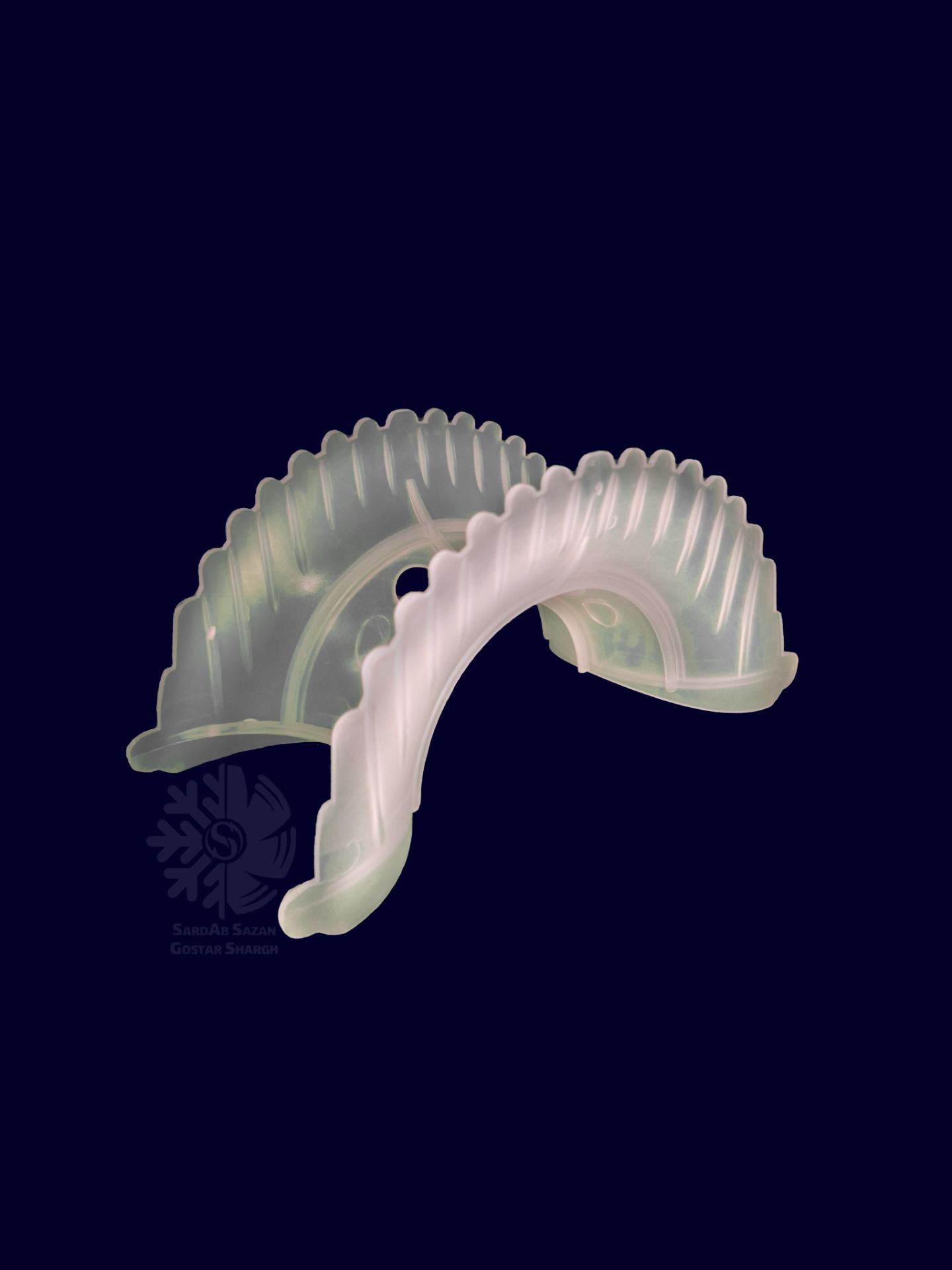

Cooling tower fills (packings) are one of the most critical components of industrial cooling systems, responsible for increasing the contact surface area between water and air. These components play a key role in enhancing heat transfer efficiency, reducing energy consumption, and optimizing cooling tower performance.

However, environmental factors, water quality, and operating conditions can lead to problems in the fills. These issues can reduce system efficiency, increase energy consumption, and raise maintenance costs. In this article, we will examine the common problems of cooling tower fills and provide effective solutions to resolve them.

1. Scaling and Clogging in Cooling Tower Fills (Packings)

The Problem:

One of the most common problems with fills is scaling caused by the dissolved solids in the water. As the water evaporates, minerals and inorganic compounds like calcium and magnesium precipitate on the surface of the fills, leading to reduced airflow and decreased heat exchange efficiency.

Symptoms of Scaling in Fills:

✔ Reduction in cooling tower efficiency

✔ Increase in water and energy consumption

✔ Reduced airflow

✔ Increase in cooling tower outlet water temperature

Solutions:

✅ Using water softening systems: These systems prevent the entry of mineral deposits into the fills (packings).

✅ Adding anti-scaling agents (Antiscalant): Using specific chemical agents to prevent the formation of deposits/scale.

✅ Using anti-scaling fills: Some PP (Polypropylene) and PE (Polyethylene) fills have designs that reduce the potential for scale formation.

✅ Periodic cleaning of fills: Cleaning with weak acids or mechanical methods increases the lifespan of the fills.

2. Growth of Algae and Bacteria in Fills (Packings)

The Problem:

High humidity in cooling towers provides a suitable environment for the growth of algae, bacteria, and fungi. This can lead to reduced heat transfer, increased pressure drop, and clogging of the water and air passages.

Symptoms of Algae and Bacteria Growth:

✔ Discoloration of fills (packings) to green or brown

✔ Unpleasant odor emanating from the cooling tower

✔ Increased pressure drop in the system

✔ Reduced cooling efficiency

Solutions:

✅ Use of biocidal substances (Biocide): Chemicals such as chlorine or bromine help reduce microbial growth.

✅ UV light and ozone: Using disinfection systems with UV light or ozone injection to control microbial growth.

✅ Improved air circulation: Increasing airflow speed to prevent the formation of an environment suitable for algae growth.

✅ Periodic washing of packings: Cleaning the packings using chemical or physical methods.

Physical damage and breakage of packings

The Problem:

Packings are exposed to mechanical stresses, high temperatures, and corrosive chemicals. These factors can cause brittleness, cracking, or the deterioration of the packings’ structure.

Signs of physical damage:

✔ Deformation of the packings

✔ Cracking and fragmentation of packing layers

✔ Reduced uniformity of water and air distribution

✔ Increased pressure drop in the cooling tower

Solutions:

✅ Choosing suitable packings: Using PP and PE packings that have higher resistance to impact and heat.

✅ Periodic inspection and preventive maintenance: Regular checks of the packings to detect early signs of breakage.

✅ Preventing severe temperature fluctuations: Reducing sudden temperature changes to avoid deformation of the packings.

✅ Proper installation of packings: Standard installation to prevent additional stress on the packings.

Gradual decline in packing efficiency over time

The Problem:

Over time, cooling tower packings lose their initial efficiency. This can be due to wear, deposit buildup, and structural changes.

Signs of declining efficiency:

✔ Increased power consumption of cooling tower fans

✔ Inadequate reduction of the outlet water temperature

✔ Increased system failures

Solutions:

✅ Periodic replacement of packings: Depending on the type of packing and operating conditions, packings should be replaced every 3 to 5 years.

✅ Use of high-quality and durable packings: Selecting packings with high longevity and corrosion resistance.

✅ Optimizing cooling tower operating conditions: Regularly monitoring system performance to reduce stress on the packings.

Conclusion

Cooling tower packings have a direct impact on the efficiency of industrial cooling systems. Fouling, algae growth, physical damage, and declining performance are common packing issues that, if left unaddressed, can lead to increased operational costs.

✅ With regular maintenance, the use of high-quality packings, and adherence to hygiene and technical standards, the lifespan of packings can be extended, and the cooling tower’s efficiency can be maintained at an optimal level.

📞 Consultation and purchase of cooling tower packings

If you are looking for high-quality and durable packings for your cooling tower, Sardab Sazan Gostar Shargh Company, offering specialized solutions and products with global standards, is ready to collaborate with you.

📞 تماس با ما: 09154002108

📧 ایمیل:info@sardabsazan.com

🚀 Experience quality, efficiency, and durability with us!