In industrial cooling systems, scaling is one of the biggest challenges, which can lead to reduced heat transfer efficiency, increased energy consumption, and higher maintenance and repair costs. Sardab Sazan Gostar Shargh Company has introduced advanced anti-fouling packings, providing an effective solution to this problem. These packings, made with advanced materials and engineered design, offer high resistance to scaling and enhance the cooling performance of cooling towers.

In this article, we examine the features, benefits, and impact of anti-fouling packings on the performance of cooling towers. We will also provide a comparison between these packings and traditional packings to highlight the importance of this new technology.

۱. Why is scaling in cooling tower packings problematic?

In cooling towers, water contains mineral salts such as calcium carbonate, sulfates, and silica. As water evaporates and the concentration of these minerals increases, deposits form on the packings and heat exchange surfaces, causing the following issues:

🔴 Reduced heat transfer efficiency: Deposit layers hinder effective contact between water and air, lowering cooling performance.

🔴 Increased energy consumption: To compensate for reduced efficiency, fans and pumps must operate at higher power, raising electricity costs.

🔴 Shortened equipment lifespan: Deposits cause corrosion of components and clog water pathways, leading to more frequent failures and repair costs.

🔴 Higher maintenance and cleaning costs: Towers with scaling require anti-scaling chemicals and continuous maintenance, increasing operational expenses.

✅ Solution: Use anti-fouling packings to prevent these problems!

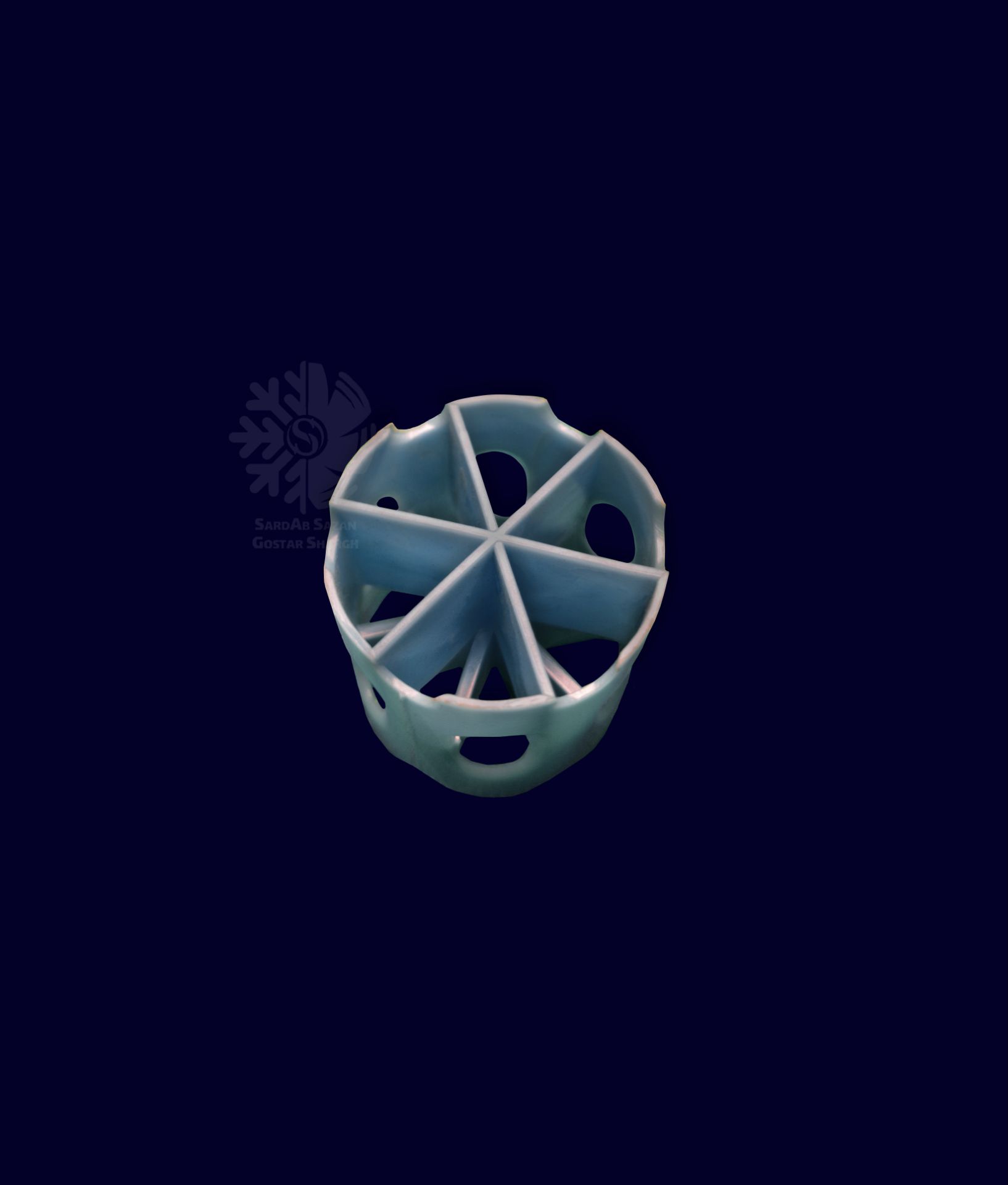

۲. What are anti-fouling packings and how do they work?

Anti-fouling packings are made from engineered materials such as modified polypropylene (PP) and polyethylene (PE), which have the following characteristics:

✔ Smooth, non-stick surface that prevents the accumulation of deposits and mineral salts.

✔ Special design with wider channels that ensures uniform water flow and reduces the likelihood of scaling.

✔ High resistance to corrosion and chemicals, extending the packing’s lifespan.

✔ Increased water-air contact surface, enhancing evaporation and lowering water temperature.

✅ Result: Anti-fouling packings significantly reduce scaling-related issues and improve the cooling system’s efficiency.

۳. Comparison of anti-fouling packings with traditional packings

✅ Result: Compared to traditional packings, anti-fouling packings offer higher efficiency, lower maintenance requirements, and reduced energy consumption.

۴. Benefits of using anti-fouling packings in cooling towers

✅ Up to 80% reduction in scaling: Thanks to the smooth, non-stick surface, the new packings prevent deposit buildup.

✅ Extended cooling tower lifespan: Reduced scaling leads to less corrosion and equipment failure.

✅ Lower maintenance costs: Reduced need for chemicals and acid cleaning lowers repair and maintenance expenses.

✅ Optimized energy consumption: Better packing performance decreases electricity and water usage.

✅ Environmentally friendly: By reducing chemical and energy consumption, these packings are a more sustainable option.

۵. Applications of anti-fouling packings in various industries

These types of packings are used in cooling towers in the following industries:

🏭 Petrochemical and refineries: Prevent scaling and increase efficiency.

⚡ Power plants: Reduce water and energy consumption in cooling systems.

🚗 Automotive industry: Optimize cooling system performance in factories.

🥛 Food and dairy industry: Prevent microbial contamination in cooling systems.

💊 Pharmaceutical industry: Maintain hygienic conditions by reducing bacterial growth in cooling towers.

۶. How to choose the right anti-fouling packing?

To select the appropriate packing, consider the following points:

🔹 Type of water used (hardness, mineral content, and chemical composition).

🔹 Temperature and environmental conditions in which the cooling tower operates.

🔹 Size and design of the cooling tower and the extent of packing contact with airflow.

🔹 Specific industry requirements (e.g., in chemical environments, more resistant packings are needed).

✅ Sardab Sazan Gostar Shargh Company offers custom PP and PE anti-fouling packings, tailored to your industry’s needs, providing an optimal solution to increase efficiency and reduce costs.

Conclusion: Why should we use anti-fouling packings?

🔹 Reduce operational costs by preventing scaling and lowering chemical usage.

🔹 Increase cooling efficiency and reduce energy consumption.

🔹 Extend equipment lifespan and decrease maintenance and repair costs.

🔹 Environmentally friendly by reducing water and chemical consumption.

💡 If you are looking for an efficient solution to optimize your cooling tower’s performance, contact our expert team at Sardab Sazan Gostar Shargh Company today and choose the best anti-fouling packing for your industry! 🚀

📞 تماس با ما: 09154002108

📧 ایمیل:info@sardabsazan.com

🚀 Experience quality, efficiency, and durability with us!