In the field of mechanical engineering, chillers are more than simple cooling devices; they are complex refrigeration systems and a vital part of industrial and building infrastructure. Selecting, designing, and optimizing a chiller system requires a deep understanding of operational principles, technical specifications, and economic and environmental considerations. This article serves as a technical guide, providing a comprehensive overview of different types of chillers and their engineering criteria.

1.Vapor-Compression Chillers

The operation of these chillers is based on the thermodynamic vapor-compression cycle of the refrigerant. The efficiency of a vapor-compression chiller is primarily measured by its Coefficient of Performance (COP), which is the ratio of the heat removed from the evaporator to the electrical work input to the compressor.

Classification based on compressor type and technical specifications:

The choice of compressor—the heart of the chiller—determines the system’s capacity, efficiency, and lifespan.

- Reciprocating chillers use a piston’s back-and-forth motion to compress the refrigerant. Although they were common in the past, their lower efficiency, higher noise, and greater maintenance needs make them mainly suitable today for low-capacity or older systems.

- Scroll chillers use two metal spirals—one fixed and one orbiting—to compress the refrigerant continuously. This design provides higher efficiency, lower vibration, and reduced noise. Their compact size and reliable performance make them ideal for modular HVAC systems and small to medium commercial projects.

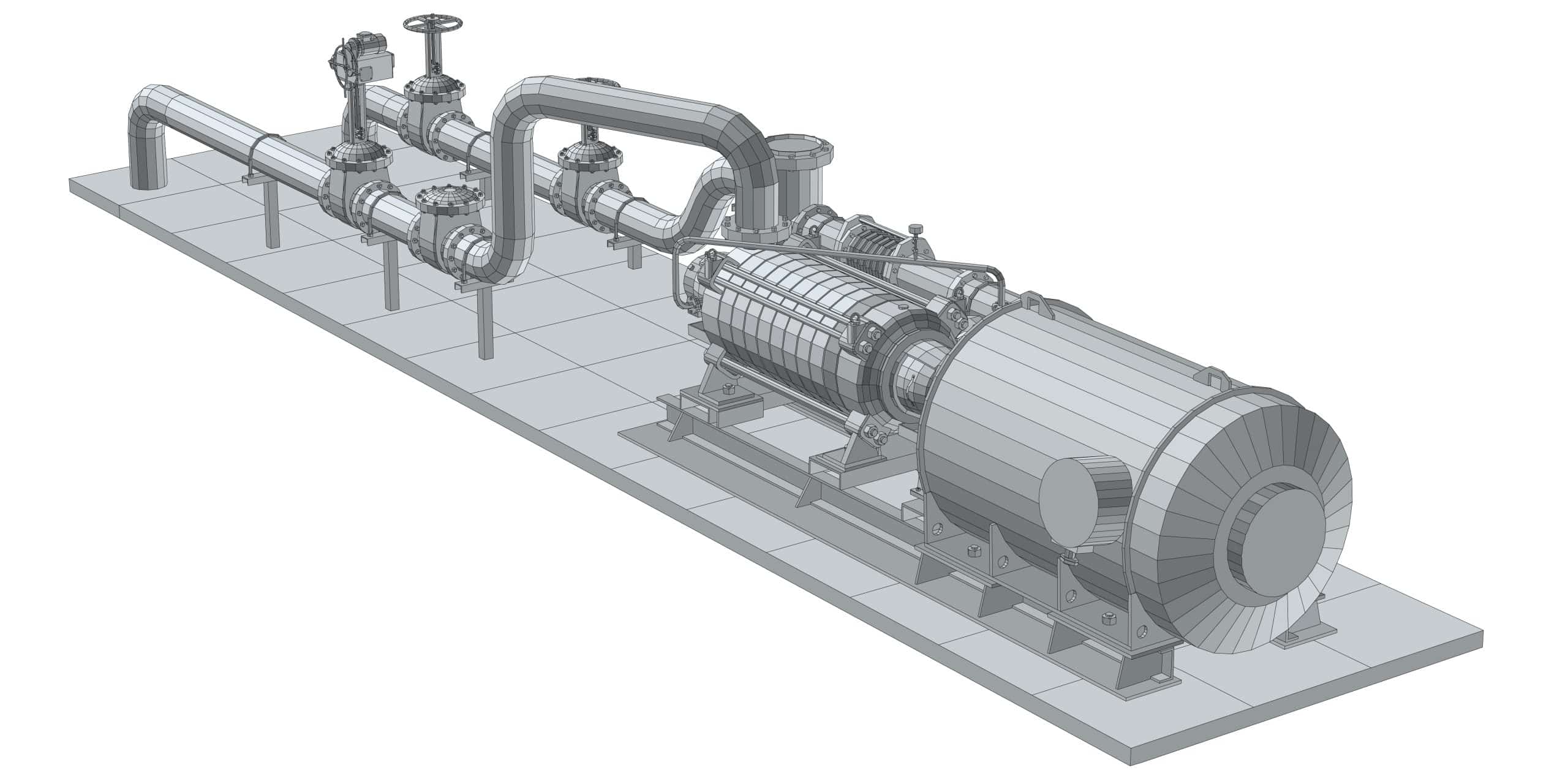

- Screw chillers use two intermeshing helical rotors (male and female) to compress the refrigerant. Their main advantages include stepless capacity control and high efficiency under partial-load conditions, making them ideal for buildings with variable cooling demands. These chillers are commonly used in medium to high-capacity applications and, thanks to their robust construction, offer a long service life.

- Centrifugal chillers use centrifugal force to compress the refrigerant at very high speeds. Due to their very high coefficient of performance (COP), especially in large-capacity applications, they achieve the highest efficiency among vapor-compression chillers. Adding a Variable Speed Drive (VSD) significantly improves their part-load efficiency. These chillers are unmatched choices for large-scale projects such as refineries, airports, and data centers.

2.چیلرهای جذبی (Absorption Chillers)

Absorption chillers use a thermal energy source (such as steam, hot water, or natural gas) instead of electricity to drive the refrigeration cycle. These systems operate based on the absorption of a refrigerant (water) by an absorbent (lithium bromide).

Classification based on the number of operating stages:

- Single-Effect: These chillers use a single generator to produce refrigerant vapor. Their coefficient of performance (COP) is typically between 0.6 and 0.8.

- Double-Effect: By adding a high-pressure generator and reusing the waste heat from the first generator, the efficiency of these chillers is significantly improved, and their COP reaches approximately 1.1 to 1.3.

- Triple-Effect: These systems, by adding a third generator, utilize more heat and provide the highest efficiency among absorption chillers, with a COP of up to 1.7.

3.Refrigerants and Environmental Considerations

Selecting the appropriate refrigerant not only affects chiller performance but also has significant environmental implications. The two main indicators in this regard are:

- Ozone Depletion Potential (ODP): The impact of the refrigerant on the ozone layer. First-generation refrigerants (CFCs and HCFCs) had high ODP values.

- Global Warming Potential (GWP): The impact of the refrigerant on global warming. New-generation refrigerants (HFCs and HFOs) have lower GWP values.

Today, the use of environmentally friendly refrigerants such as R-134a and new-generation HFOs (e.g., R-1234ze), which have near-zero ODP and GWP, is on the rise.

4.Technical and Economic Comparison

| Feature | Water-Cooled Vapor-Compression Chiller | Double-Effect Absorption Chiller |

| Primary Energy Source | Electricity | Heat (steam, hot water) |

| Coefficient of Performance (COP) | 3.5 to 6.5 (depending on the type of compressor) | 1.1 to 1.3 |

| Initial Cost | Medium to high | Very high |

| Operating cost | High (dependent on electricity cost) | Low (dependent on free/cheap heat source) |

| Maintenance | Compressor mechanical complexity | Vacuum maintenance and solution control |

| Primary application | Large buildings, industrial facilities | Utilization of waste heat, CHP (Combined Heat and Power) |

5.System Optimization and Control

An engineer should view the chiller as part of an integrated system. The Building Management System (BMS) plays a key role in optimizing chiller performance. The following strategies are essential for reducing energy consumption:

- Chiller Sequencing: Starting and stopping chillers in a way that ensures the most efficient units are always in operation.

- Pump and Fan Speed Control: Using Variable Frequency Drives (VFDs) for pumps and cooling tower fans to match partial loads and reduce energy consumption.

- Increasing Chilled Water Temperature: Raising the chiller’s outlet water temperature by one degree can lead to a significant reduction in energy consumption.

Ultimately, selecting the right chiller is a complex engineering decision that must be made through careful analysis of life-cycle costs, system efficiency under varying conditions, and environmental considerations.