Comprehensive Guide to Cooling Towerr Packing: Types, Advantages, and Selecting the Best Option

Cooling tower packing is one of the most vital components for increasing heat exchange efficiency and reducing energy consumption in industrial cooling systems. Selecting the appropriate fill can have a significant impact on the optimal performance of the cooling tower, reduced scaling, extended equipment lifespan, and lower operational costs.

In this article, we will examine the types of cooling tower fills, including PVC, PP (Polypropylene), PE (Polyethylene), and ceramic, discuss the advantages and disadvantages of each, and finally provide guidance on selecting the best option.

What is Cooling Tower Packing and Why is it Important?

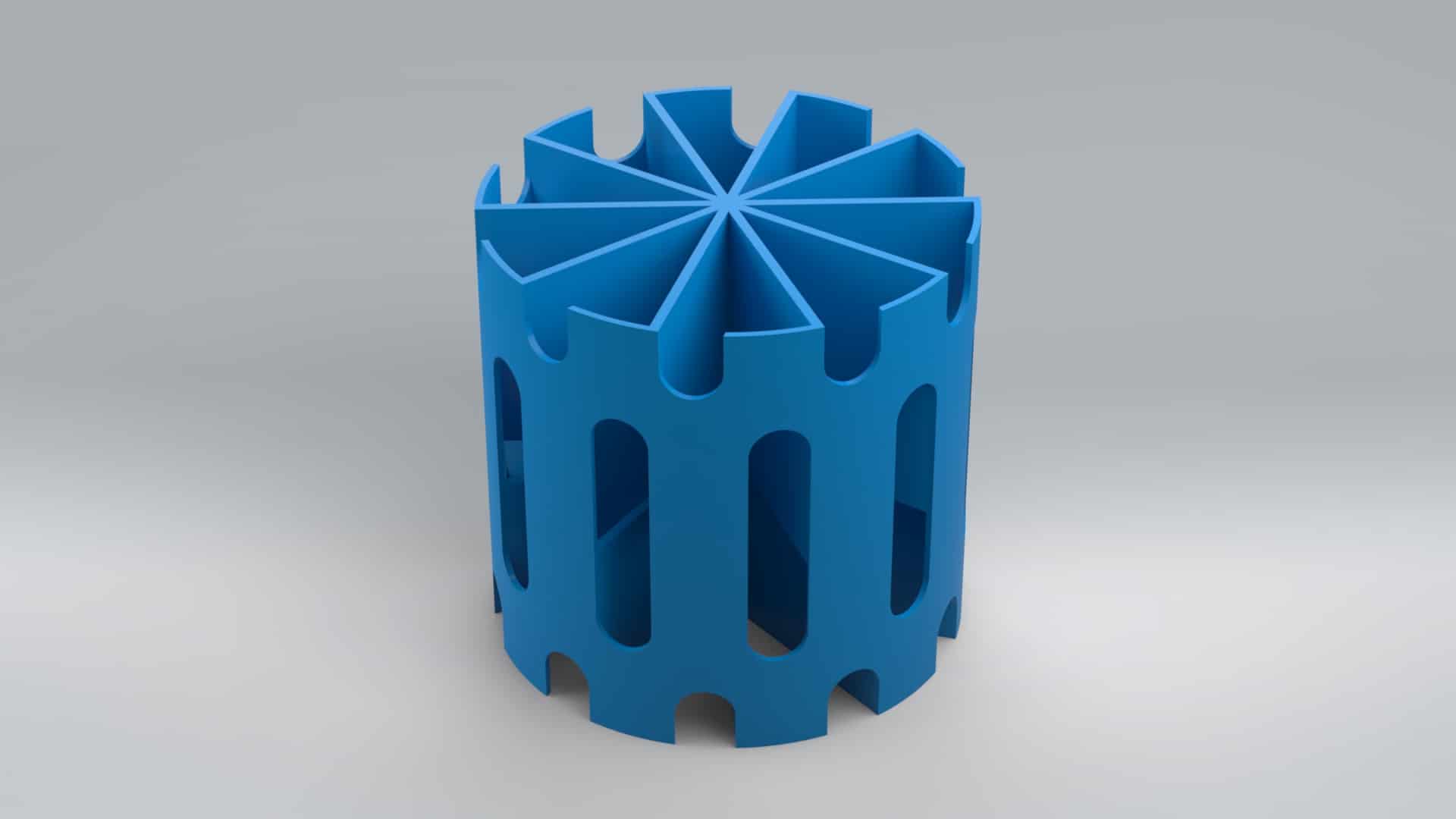

Fill (Packing) or heat transfer media is one of the key components of a cooling tower, which optimizes heat exchange efficiency by increasing the contact surface area between water and air.

Characteristics of an Ideal Fill (Packing):

✅ High contact surface area for increased heat transfer

✅ Resistant to corrosion, scaling, and chemicals

✅ High durability (long lifespan) and reduced need for maintenance and replacement

✅ Minimum pressure drop for optimizing cooling tower performance

Types of Cooling Tower Fill (Packing) and Their Comparison

1. PVC Fill (Polyvinyl Chloride) – An Economical and Widely Used Option

PVC fill is one of the most common types of fill in open-circuit and closed-circuit cooling towers. This type of fill is used in many industries due to its reasonable price and desirable performance.

✅ Advantages: ✔ Economical and cost-effective price

✔ Resistant to corrosion and chemicals

✔ Lightweight and easy to install

✔ Thermal resistance up to 60 degrees Celsius

❌ Disadvantages: ❌ Sensitivity to high temperatures (deformation at temperatures above 60 degrees Celsius)

❌ Shorter lifespan compared to PP and PE fills

❌ Low resistance to mechanical impact and pressure

✅ Suitable for:

🔹 Open-circuit cooling towers

🔹 Food industries, HVAC, and small factories

🔹 Controlled-temperature environments

2. PP Fill (Polypropylene) – Resistant and Durable

PP fill is a more advanced option than PVC and has higher resistance to temperature, chemicals, and scaling.

✅ Advantages: ✔ High thermal resistance up to 90 degrees Celsius

✔ Longer lifespan compared to PVC

✔ Excellent resistance to acids and corrosive materials

✔ Minimum scaling and reduced need for maintenance

❌ Disadvantages: ❌ Higher price compared to PVC fill

❌ Heavier weight, requiring a stronger structure

✅ Suitable for:

🔹 Oil, petrochemical industries, and power plants

🔹 Cooling towers with high operating temperatures

🔹 Industrial environments with corrosive compositions

3. PE Fill (Polyethylene) – Resistant to Impact and Chemicals

PE fills have great similarity to PP but are more resistant to impact and abrasion. This type of fill is recommended in conditions where the likelihood of physical damage is high.

✅ Advantages: ✔ High resistance to impact and mechanical pressure

✔ Greater durability compared to PVC

✔ Chemical resistance similar to PP

✔ Resistant to cracking and abrasion

❌ Disadvantages: ❌ Higher price compared to PVC

❌ Heavier weight, requiring reinforcement of the tower structure

✅ Suitable for:

🔹 Cooling towers under high mechanical stress

🔹 Corrosive environments similar to PP

🔹 Conditions where impact resistance is important

4. Ceramic Fill – The Most Resistant Type of Fill

Ceramic fill is designed for high-temperature environments and severely corrosive conditions, and is primarily used in heavy industries.

✅ Advantages: ✔ Exceptional thermal resistance (over 100 degrees Celsius)

✔ Very long lifespan and resistance to corrosion

✔ No deformation under severe environmental conditions

✔ Minimum pressure drop for optimal performance

❌ Disadvantages: ❌ High cost compared to other fills

❌ Heavy weight and more difficult installation

✅ Suitable for:

🔹 Power plants and oil refineries

🔹 Chemical industries with high temperature and pressure

🔹 Highly corrosive and polluting environments

Conclusion: Which Packing Should We Choose?

🔹 If low cost and suitable efficiency are your priority $\rightarrow$ PVC fill is the best option.

🔹 If you desire high thermal resistance and a longer lifespan $\rightarrow$ choose PP or PE fill.

🔹 If you operate in an environment with severe chemical and high-temperature conditions $\rightarrow$ ceramic fill is the best choice.

Sardab Sazan Gostar Shargh Company offers the best cooling tower fills (or packings) tailored to your needs. For a free consultation and selection of the appropriate fill (packing), contact us today!