A Cooling Tower is a critical and vital system in industrial and commercial processes that reduces the temperature of water by rejecting excess heat, making it ready for reuse. These pieces of equipment are used in various industries such as power plants, petrochemicals, food and pharmaceutical industries, and even in building HVAC systems. Given the important role of this equipment in improving energy efficiency, a more detailed understanding of cooling towers and their applications is essential.

How a Cooling Tower Works

Cooling towers are fundamentally heat exchangers that perform the cooling process by transferring heat from warm water to the air. These devices generally use two mechanisms to reduce water temperature:

1. Evaporative Cooling: A portion of the water evaporates upon contact with the air, transferring its latent heat to the air. This process helps reduce the water’s temperature.

2. Dry Cooling: The water’s heat is reduced without evaporation, through heat transfer to the ambient air. This method is typically used in closed-circuit towers.

Types of Cooling Towers

Cooling towers are categorized into different types based on their design and application. Each type has specific features and advantages that make it suitable for different conditions.

1. Open-Circuit (Wet) Cooling Tower:

In this type of tower, the warm water comes into direct contact with the air, and a portion of it evaporates. This method has high efficiency and is very suitable for processes that require rapid temperature reduction.

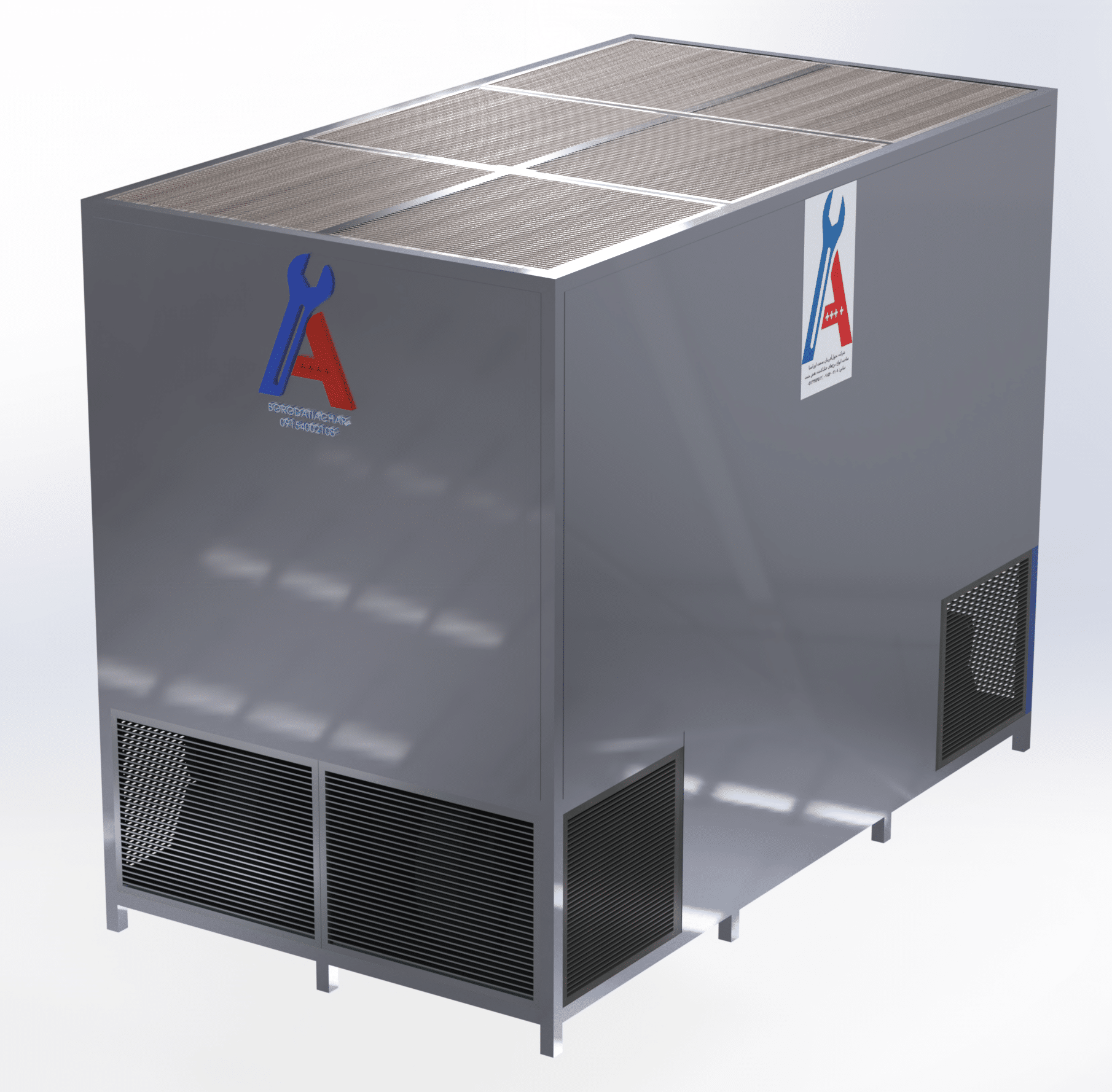

2. Closed-Circuit (Dry) Cooling Tower:

The water flows inside tubes and does not come into direct contact with the ambient air. These towers have lower water consumption but may perform less efficiently than the wet type in environments with higher temperatures.

3. Hybrid (Combined) Cooling Tower:

These towers are a combination of the features of the previous two types and are designed to reduce water and energy consumption.

Applications of Cooling Towers

Due to their high adaptability, cooling towers are used in various industries and systems:

1. Power Plants: For cooling the steam in turbines and improving the efficiency of the energy production system.

2. Petrochemical and Oil and Gas Industries: In chemical processes for reducing the temperature of fluids and equipment.

3. Food and Pharmaceutical Industries: For temperature control in sensitive production and storage processes.

4. HVAC Systems (Heating, Ventilation, and Air Conditioning): In large buildings such as hospitals, shopping centers, and hotels for cooling chiller water.

Advantages of Cooling Towers

Cooling towers play an important role in optimizing the consumption of energy and resources. Some of their advantages include:

Reduced Energy Consumption: By lowering the water temperature, the efficiency of industrial systems is increased.

Water Consumption Savings: In hybrid and closed-circuit models, water consumption is minimized.

Reduced Operational Costs: By improving the performance of cooling systems, maintenance and energy costs are decreased.

> Note: Eurasia Industry Transformers Company offers a new generation of positive pressure cooling towers, providing products with optimized performance and reduced water evaporation, which help lower operational costs and improve efficiency.

Challenges and Solutions in Cooling Tower Usage

Challenges:

Scaling and Corrosion:

Hard water can cause scaling in the packings and corrosion in the components.

High Water Consumption: In open-circuit cooling towers, water consumption can be high due to evaporation.

Solutions:

Using corrosion inhibitors and chemical additives to control scaling.

Using new technologies such as hybrid towers to reduce water consumption.

—

Why are cooling towers important?

Cooling towers not only contribute to industrial efficiency but also have positive environmental impacts. By reducing energy and water consumption, these systems help conserve natural resources and also lower operational costs for industries.

Key Considerations for Selecting the Appropriate Cooling Tower

Type of Industrial Process: The selection of the tower type must be based on the process type and its specific requirements.

Environmental Conditions: Ambient temperature and humidity have a direct impact on tower performance.

Energy and Water Consumption: Towers with optimized consumption can reduce costs in the long run.

Conclusion

Cooling towers are vital components in many industries that improve system efficiency by reducing water temperature. Selecting the appropriate tower type and maintaining it correctly can have a significant impact on overall system performance and cost reduction.